Corporate Training Programs

Professional and Technical Trainings

Aluminum Billet Casting Techniques and Quality Control

Aluminum and its alloys find a place of use in almost every area of the industry due to their excellent properties and being a “sustainable material”.

The consumption of aluminum profile products is increasing in engineering applications, especially in construction, transportation and automotive. This increase is a driving force both in the design of new alloys and in the development of new manufacturing techniques.

However, it is important to know the basic technical information in order to make economic, environment friendly and quality production.

Trainers

ERMAN CAR

Asts. Prof. Ahmet TURAN

Aluminum Melting and Refining Training

Although aluminum and its alloys are among the youngest metallic materials, due to their unique properties, they have found use in almost every area of the industry today.

Especially in the context of 'sustainability', the lightness and recyclability of aluminium and aluminium alloys is the driving force in new alloy and product design.

Melting stage is the most basic stage of aluminium semi-product and final product production process which affecting the liquid metal cost, quality and environmental part. Because of the high interest of aluminium to oxygen, the ‘risk of oxidation’ and ‘recyclability’, the variety of raw materials necessitates the understanding of melting and subsequent refining processes.

Trainers

ERMAN CAR

Asts. Prof. Ahmet TURAN

Energy Efficiency in Aluminum Facilities

In today's world, engineers and economists have two main problems on their agenda:

-

Raw material and energy constraints

-

Global climate change

Although the aluminum industry is closely affected by these two problems, unlike other materials, it also has the potential to be part of the solution to these problems.

Planned training;

-

Aluminum-energy relationship

-

Aluminum production methods and energy requirements in this processes

Energy-environment relation in aluminum production processes Energy and Exergy Concepts Energy efficiency in melting, holding, alloying and refining processes

It is aimed to share practical and the oretical information on reducing waste heat generation and evaluation of generated waste heat.

Thus , the concept of energy efficiency is intended for participants look at their

own operating conditions together with the perspective of a general aluminum-energy relationship.

Trainers

ERMAN CAR

Waste Minimization in Steel Mills and Environmental Impacts of Metals

Environmental impact mechanisms of metals in general, their effects and basic protection methods to be followed will be examined and basic rules to be followed for waste formation and minimization of wastes will be evaluated on plant sample which producing scrap steel by EAF. In addition, the basic applications that must be taken into account today's technological level will be explained. The main purpose of the training is to provide the participants with the necessary knowledge and experience in this field by providing the participants with the basic methods and practices that they can handle in their own businesses.

Trainers

prof. Dr. Servet Timur

Corrosion and Corrosion Prevention Training through Real-Life Cases

There is a risk of corrosion in any environment where metal and its alloys, which are the basic engineering

material, are used. The purpose of this training is to provide the relevant people who have not been trained in corrosion before or who have received very limited training to gain the necessary awareness and knowledge about the basic principles, economic importance and

methods of corrosion protection through real examples.

Trainers

prof. Dr. Mustafa URGEN

prof. Dr. Ali Fuat CAKIR

Waste Minimization in Foundries and Environmental Impacts of Metals

Environmental impact mechanisms of metals in general, their effects and the

basic protection methods to be followed will be examined and the basic rules

to be followed for waste formation and minimization of wastes will be evaluated

on the foundry sample. . In addition, the basic applications that must be taken

into account today's technological level will be explained. The main purpose of

the training is to provide the participants with the necessary knowledge and

experience in this field by providing the participants with the basic methods and

practices that they can handle in their own businesses.

Trainers

prof. Dr. Servet Timur

Theoretical and Operational Application of Coating Technologies (Flame, Arc, Plasma, HVOF)

Giving theoretical knowledge and practical industrial applications of thermal spraying technologies which have limited infrastructure and scientific competence in our country.

New potential for solutions to industrial problems such as abrasion, friction, corrosion, oxidation; presenting Spray Metal, Ceramic, Plastic or Composite Coating Technology to the participants.

Trainers

prof. Dr. Fatih USTEL

Surface Treatments with Electrolytic and Vacuum Coating Techniques Thermal Spraying

"Surface treatments" is the general name for the processes used to change and improve the functional, wear, decorative and corrosion properties of the surfaces of the materials used in almost all industry sectors. The subject is extremely comprehensive and in one's field of interest of many different disciplines. The topic is extremely extensive and it is of interest to many different disciplines. The basic principles of surface treatment applied to metallic materials will be summarized to the participants. All this process is explained with special emphasis and inform the participants that production, choosing, defining and usage intended for different aims of coatings.

Trainers

prof. Dr. Mustafa URGEN

prof. Dr. Ali Fuat CAKIR

Humanity: R&D and Innovation Management

The aim of this training is to provide the employees with knowledge about the concept of innovation and the building blocks of innovation culture management. For a culture of innovation, thinking people and a good management system are required.

In this training, the role of human beings in innovation and the formation of innovation culture will be discussed and the needs of

management systems necessary for the formation of innovation culture will be evaluated.

Trainers

prof. Dr. Ozgul KELES

Metallurgy for Non-Metallurgists

It aims to give knowledge and skills about the production, processing and testing of materials by explaining how metallurgy is applied in an industrial context through

scientific foundations to the people who work in the metallurgy and materials sector but are not metallurgists. Thus, it is aimed to make technical communication more

effective in the business environment and to be more knowledgeable and effective in responding to customer requests.

Trainers

ERMAN CAR

Asts. Prof. Şeref SÖNMEZ

Cathodic Protection by Sectors (Fuel Oil, LPG)

It is necessary to understand the naturally occurring corrosion and take precautions against it. The velocity of corrosion that will occur in metallic structures in soil – water – chemicals is reduced by “Cathodic Protection”. Understanding and proper application of cathodic protection is important for both human health and the economy. Pipes or tanks may be punctured as a result of incorrect and/or incomplete cathodic protection, and explosive / flammable substances may leak into the environment. It is in our hands to prevent this situation which is a threat to human life. It is very important to ensure the continuity of the cathodic protection, which is a legal requirement, by applying it correctly and measuring it correctly.

Trainer

Okan İŞDAŞ

Ribbed Construction Steel Caliber Design Workshop

As is known, ribbed construction steel, which is a final product in the long-finished category and one of the basic training topics of metallurgy and mechanical

engineering, is produced by rolling method of plastic forming theory and calibre design is one of the focus subjects of this method.

This workshop is aimed give advanced level awareness and knowledge about calibrated ribbed construction steel by simulating and detailing the subjects on real examples in the light of theoretical and practical knowledge to the people who are interested in the subject of calibrated design in

ribbed construction steel production and who have received a certain level

of training of this subject.

The training is designed to examine various sample designs in depth through a computer-based program, to simulate the real problems the participants are experiencing and will be conducted interactively with the participants.

Trainers

M. Sezai BIRİŞCI

Polymer Matrix Composite Manufacturing Techniques

The main purpose of the training is to explain the principles of the techniques used in the manufacturing of thermoplastic and thermoset based polymeric composites and to sample the applications of the parts produced by these techniques in different sectors, especially in the automotive industry.

In this training, the basic components of the composite, thermoset/ thermoplastic based matrix materials and the general characteristics of reinforcements, reinforcing forms, manufacturing technique and the required properties of the composite depending on the selection criteria for the reinforcing form and process selection criteria will be explained.

It is aimed to inform the participants about composite design, process selection and process control with the principles described in this context.

Trainers

prof. Dr. Erdem DEMIRKESEN

SEVESO - Risk Based Inspection (RBI) Corrosion Valuation

Regulation on prevention and mitigation of major industrial accidents - in 8th clause " risk assessment is performed with quantitative methods in order to evaluate risks." shaped there exists a statement. One of the tools in numerical risk assessment is “API 581 – Risk based inspection”. API 581 mainly asks for the study of corrosion in equipment and the creation of a possibility– result matrix through the results. The risk is determined according to the results in this matrix and how the risk is managed is decided. It is therefore necessary to understand the nature of corrosion and the procedures in API 581.

Trainer

Okan İŞDAŞ

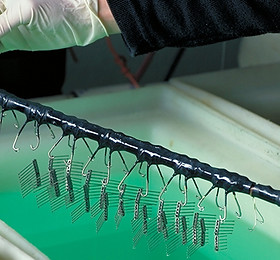

Continuous Aluminum Sheet Casting Techniques and Quality Control

Because of its excellent properties, aluminum and alloys find a place of use in almost every area of the industry. Especially in recent years, environmental problems, energy production and availability difficulties have put the concept of “sustainability” on the agenda of engineers. Aluminum is a sustainable material due to its light weight and also its recycling properties.

Especially in transportation and automotive, construction, packaging and engineering applications, the consumption of aluminum plate products is increasing. This increase is a driving force both in the design of new alloys and in the development of new manufacturing techniques.

However, the production of economic, environmentally sensitive and high quality plates and sheet products, starting from raw material supply, the process that goes up to the shipment of the product needs to be monitored and controlled very well in a technical sense.

Trainers

ERMAN CAR

Asts. Prof. Ahmet TURAN